Filter/Sort

Roloc DiscRoloc Style Surface ConditioningDynafile BeltChampion Drill BitsFiber DiscFlap DiscElectrodesBack Up Pads

Details

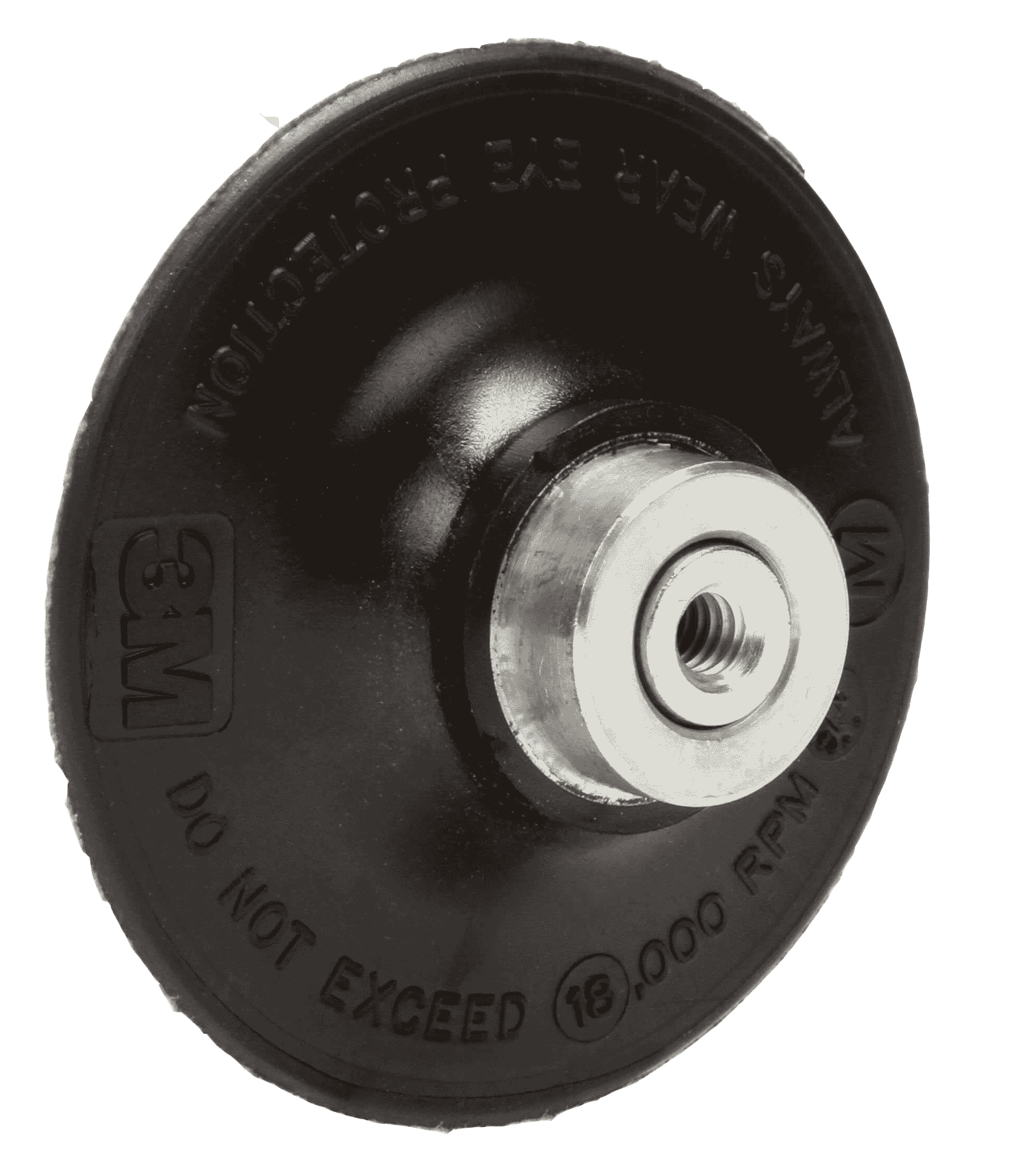

Well suited for angle grinders, our abrasive fiber discs will efficiently assist you in your next fabrication or metal-working project. Whether you are sanding, finishing, or grinding, these sanding discs are some of the best in the manufacturing and welding industry to get a professional, clean look on various metals, plastics, and woods. We offer ceramic, zirconium, and aluminum oxide sanding discs as well as plastic and rubber back-up pads to properly mount the disc on the grinder. Our abrasive fiber discs have exceptional durability and are designed to allow you to continue creating your specialty products at the highest quality.

Our impactful belts are capable of helping you with various stages of welding. Surface conditioning belts are perfect for handling any surface-treating work such as removing rust, deburring, improving finishes, removing paint coats, and more. Our dynafile belts work best on stainless steels, superalloys, and non-ferrous metals with their self-sharpening effect throughout use. Belts are offered in packs of 10 and come in many different grain options. Dynafile belts come in 40, 60, 80, and 120 grit while surface conditioning belts come in coarse, medium, or fine. Our surface conditioning and dynafile belts have a long life so that you can productively complete your job without maintenance hiccups from your belt.

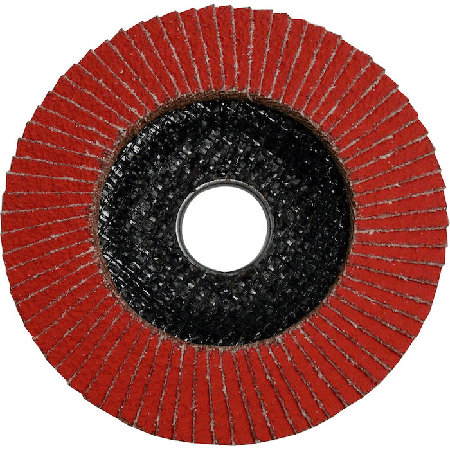

These versatile flap disc wheels are designed to be used both as a depressed center grinding wheel and as a cut-off wheel, making them ideal for cutting, grinding, gouging and more. Discs are supplied in 40, 60, and 80 grit to give you your choice of style for your project. We offer the giant Cubitron II, which attracts manufacturers for its 3M precision-shaped grain, allowing welders to cut faster than standard ceramic discs. We also have an option of a trimmable flap disc that lets users extend the disc's life by trimming the plastic back up so that every flap gets used. The flexibility of our flap disc wheels allows welders to utilize its precision at many different stages in the fabrication process. Whenever you wish to use it, we can assure you it will give you top-tier quality!

Quick-change Roloc Discs are a welder's best friend due to the infrequent maintenance and easy, device-free changing system. They are also perfect for getting into smaller areas as our quick change Roloc discs come in sizes of 2 and 3 inches as well as 36, 50, 80, and 100 grit. Non-Roloc surface conditioning discs are supplied in 2 and 3 inches as well, but specify fine, medium, or coarse for grit type. Roloc back up pads are also offered for both sizes so that you can properly mount your disc on a grinder. Your welding and fabrication projects are already laborious enough. Make it easier on you and shop our quick-change surface conditioning discs!

The Scotch-Brite™ surface conditioning disc makes tough jobs easier by achieving a burr-free, paintable finish in fewer steps, without damage to the base material. Non-woven, open web, durable construction is designed to resist loading and greatly increase the life of the disc! This makes for less frequent disc changes so that you don't have to waste time with upkeep. These discs only come in boxes of 10 with sizes of 5 or 7 inches and your choice of medium or coarse grit type. We also offer Velcro back-up pads to complement and protect your Scotch Brite™ surface conditioning disc.

Drill Fast, Accurate Holes Through Tough Materials. Such as Aluminum, Steel And Other Tough Alloys. Self-Centering 135° Split Point For Precision Drilling- Drill Will Not Walk

Ceramic Fiber Disc, 4 1/2 x 7/8 x 100 Grit, Pk 25

100 Grit

$0.88

Pack Of 25

Ships Within 1 Business Day

Aluminum Oxide Fiber Disc, 4 1/2 x 7/8 x 24 Grit, Pk 25

24 Grit

$0.68

Pack Of 25

Ships Within 1 Business Day

Aluminum Oxide Fiber Disc, 4 1/2 x 7/8 x 36 Grit, Pk 25

36 Grit

$0.65

Pack Of 25

Ships Within 1 Business Day

Aluminum Oxide Fiber Disc, 4 1/2 x 7/8 x 50 Grit, Pk 25

50 Grit

$0.62

Pack Of 25

Ships Within 1 Business Day

Aluminum Oxide Fiber Disc, 4 1/2 x 7/8 x 60 Grit, Pk 25

60 Grit

$0.61

Pack Of 25

Ships Within 1 Business Day

Aluminum Oxide Fiber Disc, 4 1/2 x 7/8 x 80 Grit, Pk 25

80 Grit

$0.59

Pack Of 25

Ships Within 1 Business Day

Aluminum Oxide Fiber Disc, 4 1/2 x 7/8 x 100 Grit, Pk 25

100 Grit

$0.58

Pack Of 25

Ships Within 1 Business Day

Aluminum Oxide Fiber Disc, 5 x 7/8 x 24 Grit, Pk 25

24 Grit

$0.80

Pack Of 25

Ships Within 1 Business Day

Aluminum Oxide Fiber Disc, 5 x 7/8 x 36 Grit, Pk 25

36 Grit

$0.76

Pack Of 25

Ships Within 1 Business Day

Aluminum Oxide Fiber Disc, 5 x 7/8 x 50 Grit, Pk 25

50 Grit

$0.73

Pack Of 25

Ships Within 1 Business Day

Aluminum Oxide Fiber Disc, 5 x 7/8 x 60 Grit, Pk 25

60 Grit

$0.71

Pack Of 25

Ships Within 1 Business Day

Aluminum Oxide Fiber Disc, 5 x 7/8 x 80 Grit, Pk 25

80 Grit

$0.68

Pack Of 25

Ships Within 1 Business Day

Aluminum Oxide Fiber Disc, 5 x 7/8 x 100 Grit, Pk 25

100 Grit

$0.67

Pack Of 25

Ships Within 1 Business Day

Aluminum Oxide Fiber Disc, 7 x 7/8 x 24 Grit, Pk 25

24 Grit

$1.44

Pack Of 25

Ships Within 1 Business Day

Aluminum Oxide Fiber Disc, 7 x 7/8 x 36 Grit, Pk 25

36 Grit

$1.32

Pack Of 25

Ships Within 1 Business Day

Aluminum Oxide Fiber Disc, 7 x 7/8 x 50 Grit, Pk 25

50 Grit

$1.29

Pack Of 25

Ships Within 1 Business Day

Aluminum Oxide Fiber Disc, 7 x 7/8 x 60 Grit, Pk 25

60 Grit

$1.24

Pack Of 25

Ships Within 1 Business Day

Aluminum Oxide Fiber Disc, 7 x 7/8 x 80 Grit, Pk 25

80 Grit

$1.20

Pack Of 25

Ships Within 1 Business Day

Aluminum Oxide Fiber Disc, 7 x 7/8 x 100 Grit, Pk 25

100 Grit

$1.18

Pack Of 25

Ships Within 1 Business Day

Roloc Style - -Surface Conditioning Disc, 2" x Coarse, Pk 50

Coarse Grit

$0.95

Pack Of 50

Ships Within 1 Business Day

Roloc Style -- Surface Conditioning Disc, 2" x Medium, Pk 50

Medium Grit

$0.92

Pack Of 50

Ships Within 1 Business Day

Roloc Style -- Surface Conditioning Disc, 2" x Very Fine, Pk 50

Very Fine Grit

$0.91

Pack Of 50

Ships Within 1 Business Day

Roloc Style -- Surface Conditioning Disc, 3" x Coarse, Pk 50

Coarse Grit

$1.65

Pack Of 50

Ships Within 1 Business Day

Roloc Style -- Surface Conditioning Disc, 3" x Medium, Pk 50

Medium Grit

$1.60

Pack Of 50

Ships Within 1 Business Day

Roloc Style -- Surface Conditioning Disc, 3" x Very Fine, Pk 50

Very Fine Grit

$1.56

Pack Of 50

Ships Within 1 Business Day

Ceramic Dynafile Belts 1/2 x 24 x 100 Grit, Pk 25

100 Grit

$2.05

Pack Of 25

Ships Within 1 Business Day

Black & Gold 11/64" Champion Drill Bit, Pk 12

Size: 11/64"

$1.56

Pack Of 12

Ships Within 1 Business Day

Black & Gold 13/64" Champion Drill Bit, Pk 12

Size: 13/64"

$2.11

Pack Of 12

Ships Within 1 Business Day

Black & Gold 15/64" Champion Drill Bit, Pk 12

Size: 15/64"

$2.34

Pack Of 12

Ships Within 1 Business Day

Black & Gold 17/64" Champion Drill Bit, Pk 12

Size: 17/64"

$3.11

Pack Of 12

Ships Within 1 Business Day

Black & Gold 19/64" Champion Drill Bit, Pk 12

Size: 19/64"

$3.68

Pack Of 12

Ships Within 1 Business Day

Black & Gold 21/64" Champion Drill Bit, Pk 12

Size: 21/64"

$4.15

Pack Of 12

Ships Within 1 Business Day

Black & Gold 11/32" Champion Drill Bit, Pk 12

Size: 11/32"

$4.70

Pack Of 12

Ships Within 1 Business Day

Black & Gold 23/64" Champion Drill Bit, Pk 12

Size: 23/64"

$5.15

Pack Of 12

Ships Within 1 Business Day

Black & Gold 25/64" Champion Drill Bit, Pk 12

Size: 25/64"

$6.07

Pack Of 12

Ships Within 1 Business Day

Black & Gold 13/32" Champion Drill Bit, Pk 12

Size: 13/32"

$6.43

Pack Of 12

Ships Within 1 Business Day

Black & Gold 27/64" Champion Drill Bit, Pk 12

Size: 27/64"

$6.76

Pack Of 12

Ships Within 1 Business Day

Black & Gold 29/64" Champion Drill Bit, Pk 12

Size: 29/64"

$8.32

Pack Of 12

Ships Within 1 Business Day

Black & Gold 15/32" Champion Drill Bit, Pk 12

Size: 15/32"

$8.91

Pack Of 12

Ships Within 1 Business Day

Black & Gold 31/64" Champion Drill Bit, Pk 12

Size: 31/64"

$9.48

Pack Of 12

Ships Within 1 Business Day